ABOUT OEM

With experiences in manufacturing capabilities for major enterprises, we continue to adapt to new demands in technology.

Since 1953, Sengoku has continued to grow its technological and production capabilities, expanding its field of business while accepting manufacturing contracts from a wide range of companies including major Japanese manufacturers.

By handling a wide range of manufacturing capabilities tailored to the ideals of the companies we serve we have diligently grown our operations, and now provide OEM services for Japan's top manufacturers.

The growth that distinguishes Sengoku's OEM business is a history of adapting new technologies to serve our customers' needs.

We believe that our experience and achievements are a bridge to our future endeavors and serve as an important foundation for reliability and high expectations among our customers.

【The OEM Record】

Integrated production, mass production

Our Commitment to Maximizing Added Value for Our Customers

Sengoku's Integrated Production System Refined for Mass Production Operations

From design and development to product manufacturing itself, all of our processes fall under an integrated system of production.

Our facilities support mass production operations, and each of our departments come together as one to realize dedicated and flexible craftsmanship and manufacturing.

【OEM Manufacturing Achievements】

2017~2021 Results

Process

Mass Production Process

Equipped with the systems and facilities to complete integrated processing in-house.

【Using Mold to Achieve High Output】

Molds are the foundation of manufacturing.

We design and produce our molds in house.

- We can also process large molds using a large electrical discharge machine.

- Maintenance of mass production molds is also performed in-house, allowing us to immediately respond to any sudden issues.

- We manufacture molds that are resistant easy to produce, to defects and safe proactively pushing for further automation and optimization to ensure high quality, low cost, and quick delivery time.

【Various manufacturing locations】

Based in Japan, China, and the Philippines.

Our system company is equipped to provide high quality and quick delivery by determining the optimal production factory among our manufacturing bases in Japan, China, and the Philippines (all in-house factories) and making various adjustments from the design stage that are tailored for mass production.

The Head Office Factory

The Head Office Factory Sengoku Aladdin Factory

Sengoku Aladdin Factory Ueno Factory

Ueno Factory Miyamae Factory

Miyamae Factory 東莞千石家電有限公司

東莞千石家電有限公司 千石家電(恵州)有限公司

千石家電(恵州)有限公司 Philippines Factory

Philippines Factory

Planning and Solutions Capabilities

Manufacturing Creating Further Added Value

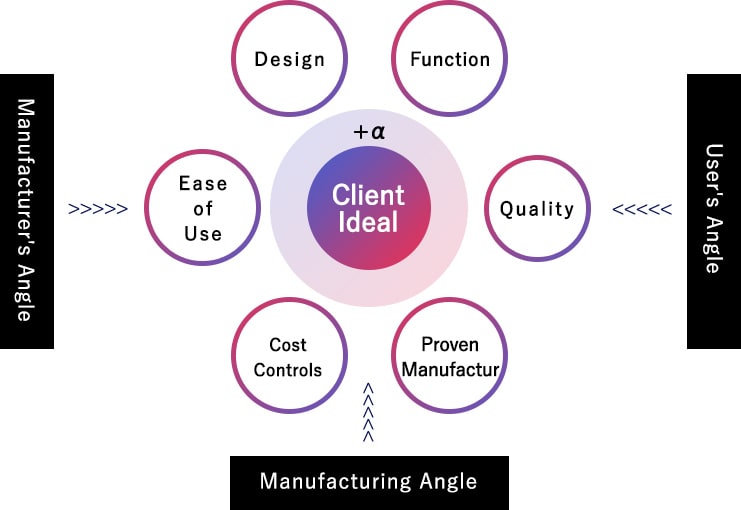

■Working to Increase Value from three perspectives

We strive to offer the optimal method that will meet our customer's needs.

We look at function, quality, cost, usability, design, and other factors through the lens of the customer and manufacturer , then use our knowledge, experience, and technology as an expert in manufacturing to provide added value unique to Sengoku.

■Working Closely with the Customer as a Team

We have developed alongside our technology, refining our OEM services while meeting the diverse needs of our wide-ranging customers.

Rather than simply following our customer's demands, we offer solutions while making considerations for parts and manufacturing methods that control for cost, working closely with the customer to determine the necessary means for mass production that meets the ideal form.

Design Capabilities and Inquisitive Approach

Refining the product prior to production.

■ Designed for Mass Production Without Compromising Ideals

We meet the customer's ideal form from the design stage, determining whether the form is reproducible for mass production. Understanding the essential needs, we achieve the ideal form while proposing designs and alternative options.

■ Designed to Meet Overseas Standards

From the design stage, we come up with designs that meet both Japanese standards and overseas certification criteria. This helps to increase the potential of future sales channels and overseas expansion.

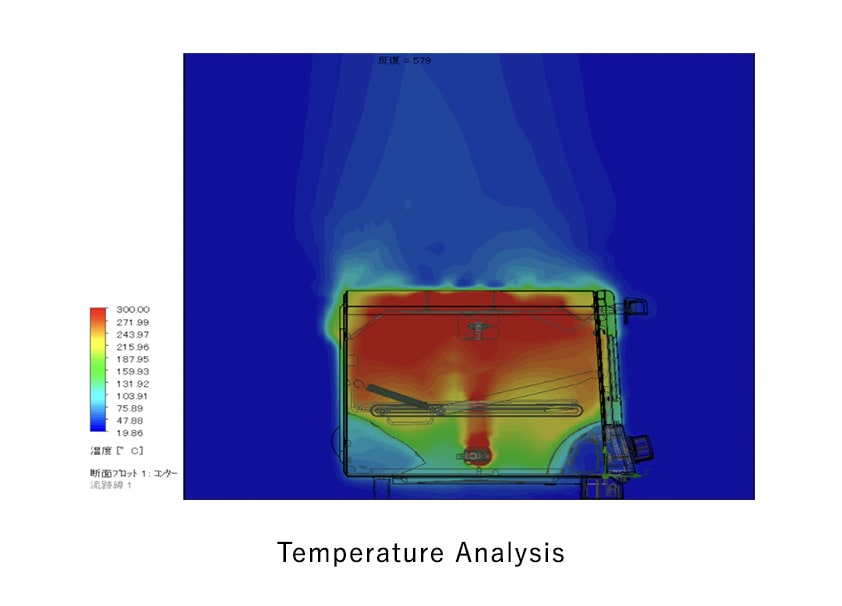

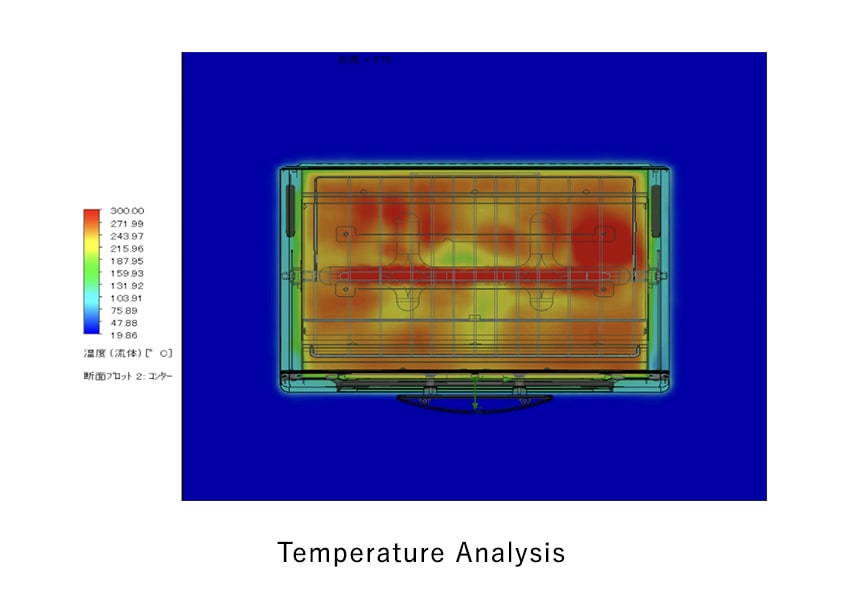

■ Introducing Structural Analysis Software into Design Workflow

During the prototype stage of design, we carry out analysis using simulations, and calculate product performance and functionality by analyzing heat conduction, fluid mechanics, and strength.

This upstream analysis of the manufacturing process helps to achieve an even more ideal form, further improving quality, reducing cost, and shortening delivery time.

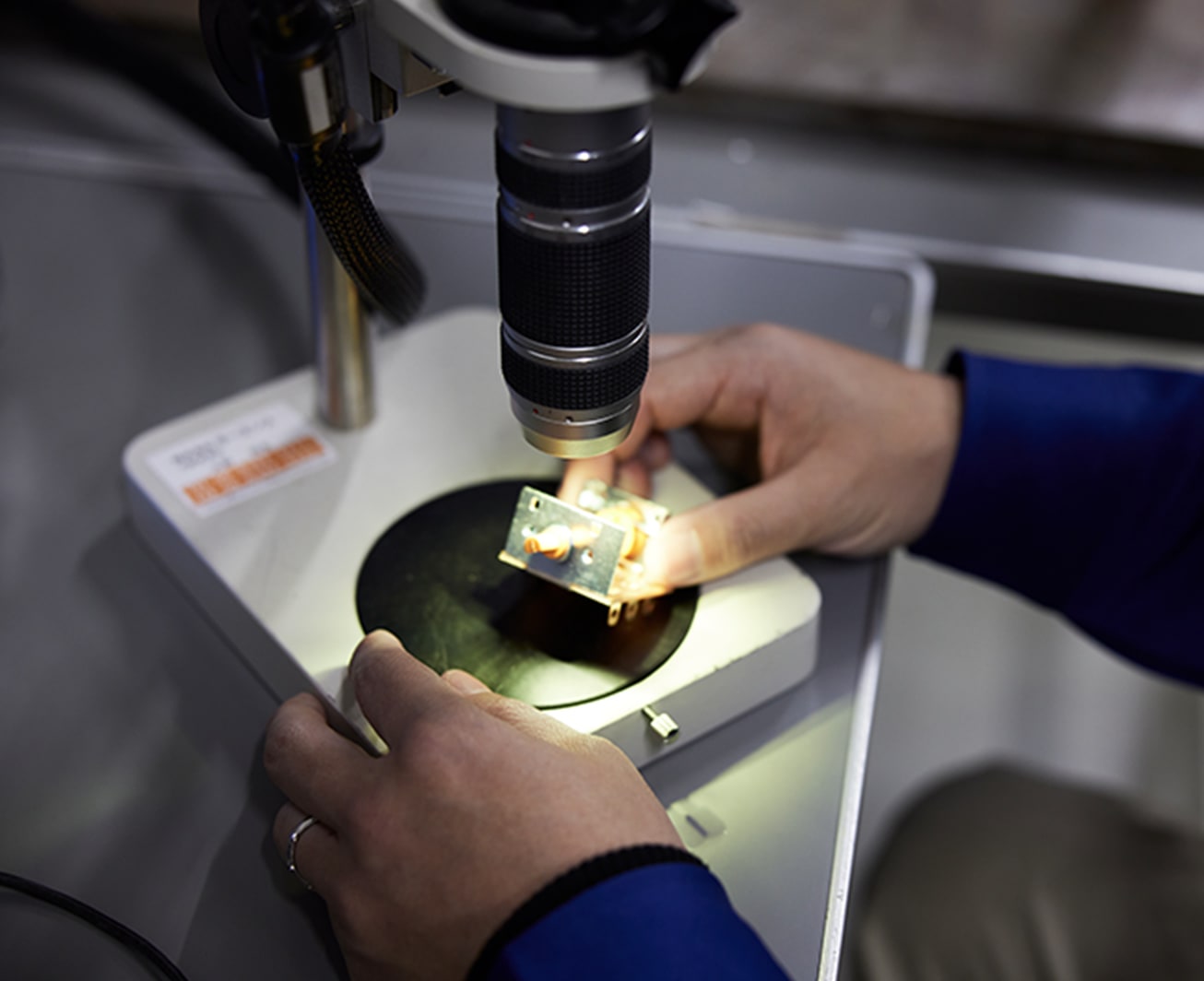

Manufacturing Technologies and Systems

Evolving Mass Production Technologies and Systems Through Sengoku's Comprehensive Capabilities

■ Refining Mass Production

Even with integrated production, properly handling mass production operations can be difficult.

We are focusing our efforts to improve mass production technologies through a never-ending pursuit for knowledge, technical capabilities, and manufacturing capabilities, which have been cultivated through our past OEM experience.